As the clock ticks toward a midnight September 14 deadline on negotiations between my union, the United Auto Workers (UAW), and the Big Three automakers (Ford, General Motors, and Stellantis), UAW President Shawn Fain has made headlines by demanding a 40 percent raise (much like our CEOs have received), proposing reductions to work weeks that have ballooned to 84 hours for some, and tossing Stellantis’s insulting counter-offer into the trash on Facebook Live.

Eliminating tiers is the highest priority for many workers. What this means in practice is a bit complicated, especially on the electric vehicle (EV) front. Tiers are endemic to EV construction across the Big Three. EV workers suffer from worse pay and benefits and less job security than their counterparts making conventional automobiles.

Some EV construction now happens under low-wage joint ventures like Ultium (General Motors and LG), but tiers under existing UAW contracts are already fulfilling much of our EV work.

One thing is clear: the elimination of tiers that pay joint-venture battery workers far less, as well as all other tiers, is necessary for a just transition to green manufacturing and infrastructure. Fighting climate change must not come at the expense of workers’ livelihoods — we all deserve the same rights, benefits, and pay.

A Labyrinth of Tiers

Of the Big Three, General Motors seems to have the most dizzying array of legal entities covered under our collective bargaining agreements. I’ve heard that EV drive units and batteries are currently made by workers employed by Ford and not some other entity, but I’m willing to bet that Ford’s joint EV venture with SK Innovations, BlueOval SK, would prefer its own contract with the UAW similar to Ultium’s. Ditto for StarPlus Energy, Stellantis’s joint venture with Samsung SDI.

General Motors Component Holdings (GMCH) was created to establish a lower tier for parts workers, and it is one entity where workers are making parts for EVs. Operations in Rochester and Lockport, New York, build EV battery cooling lines and stators. GMCH workers’ starting rate as of the 2019 contract was $16.25.

Eight years is a long time, especially since our contracts last only four years. After a 40-day strike at General Motors in 2019, GMCH workers were left behind: after eight years of seniority they could still reach just under 70 percent of maximum pay for assembly workers. When the 2019 contract was ratified, it was no surprise that workers at GMCH overwhelmingly rejected it.

The eight-year wage progression is not an outlier among tiers within the UAW–Big Three contracts. Another entity under the master agreement, Customer Care and Aftersales (CCA), has an eight-year progression starting at $17 an hour and ending at $31.57. That is, unless you were hired on or after November 16, 2015: those CCA workers top out at just $25. CCAs are distribution centers that deliver parts to dealerships and other repair shops all over North America, and they will be just as important to EVs as they have been for internal combustion engine vehicles.

That brings us to GM Subsystems, a wholly owned subsidiary of General Motors formed in 2009 as part of the restructuring after the federal bailout. My first experience with GM Subsystems was in 2014. Dozens of General Motors temporary workers, many with over two years on the job, were reclassified as GM Subsystems workers and given a pay cut. Material movement work, including my own job of sequencing side rearview mirrors, was brought under Subsystems when the local union reached a deal with the company upon millions being invested in three large warehouses to be constructed at Detroit-Hamtramck Assembly, where I worked. This is when I learned that concessions don’t have to wait for lean times to rear their ugly head.

In 2016 a worker joined my team who had worked at Brownstown Battery Assembly. While Brownstown was critical to GM’s electric vehicles (the Volt, the Bolt, and Bolt EUV), the workers there were considered GM Subsystems employees and started at $15, ending at $17 after four years.

The Big Three’s profit sharing is calculated on a contractual formula based on total North American profits from the previous year. The roughly 50,000 UAW General Motors workers receive $1 for every million dollars the company makes — unless they work for Subsystems, in which case they only receive $0.25 per million.

And if you’re a temp, I’m sorry that you’re even hearing about profit sharing, because you’re not getting a dime.

I can say one nice thing about Subsystems’ recent contract: it expires at the same time as the contract for other General Motors workers. So workers across General Motors and Subsystems will be able to stand in solidarity during negotiations and possibly a strike, unlike in 2019.

The different tiers of retirement benefits are also labyrinthine. General Motors workers hired after October 15, 2007, do not enjoy a pension or health care in retirement as previous generations did, and they’re instead forced to rely on various schemes of 401(k) and HSA matches and contributions, with lower-tier workers receiving less generous contributions from GM.

The Destructive Effect of Tiers

The byzantine tier system also creates inequalities in workplace rights that undermine union solidarity.

The Detroit-Hamtramck factory closed in 2020 to be reborn as Factory Zero, building the GMC Hummer EV pickup and SUV. When I returned there in July 2021, many things had changed. Just about every material-handling job was now under GM Subsystems. General Motors workers who had previously worked those jobs were now ineligible for them, due to deals we had made during contract negotiations in 2019 to keep work in my plant. All battery assembly fell under GM Subsystems as well, so even if someone wanted to, they could not transfer to jobs in that department.

That was what our union agreed to, and we’re living with the consequences of accepting lower-tier jobs with severely diminished wages and rights. Those workers deserve not only a living wage but also the respect that comes from having rights on the job.

Those rights are more easily upheld when union members who know their rights fight for those who don’t. I got a crash course in this lesson when I was first hired as a temp in 2006. After hundreds of workers retired following buyouts, CCA Pontiac brought in temps. When temps would get picked on by management, rank-and-file workers with the benefit of seniority kept an eye out and would raise hell — showing what having rights in the workplace looked like.

Unfortunately, workers in electric battery assembly in my plant have lower seniority, and because they’re in a separate part of the building, they don’t have nearly enough rank-and-file members looking out for them. Because assembly workers cannot transfer over, there’s a very real “out of sight, out of mind” effect. On top of that, they have very little in the way of representation. Until recently they’ve had to make do with one steward for their whole unit — a steward with only 30 hours a week to educate and defend their bargaining unit, the remainder of the time working a job. By comparison, the General Motors workers in the rest of the plant have a minimum of two full-time stewards.

In July 2022, contract negotiations for Subsystems workers ran up until the eleventh hour. The final morning, our steward told us GM workers that we would have to cross the Subsystem workers’ picket line or risk losing our jobs. That had been the case for the Subsystems workers during our 2019 strike, which caused some tension on the picket lines. It’s a clear example of how tiers erode solidarity and fracture workers’ unity.

With the 2022 contract, pay was raised to a maximum of $22 for materials workers and $24 for battery assemblers, although so-called temporary workers still max at $17 after four or more years. That’s right: we have in writing that workers can be considered temporary for well over four years.

Tiers Must Go

Since the day I was formally hired by GM in 2007, tiers have only gotten more complex and further embedded into our contracts. There was a time when getting your foot in the door in an auto plant meant that you could breathe a sigh of relief. Yes, it takes a while to get used to standing on your feet for most of the day, but barring (sadly common) workplace injuries, your body does eventually get used to the work. But now we have unprecedented turnover. People hang on only in the hope that things might one day get better.

Hopefully, that day is now, with a UAW leadership committed to getting rid of tiers. Eliminating tiers would reduce the number of hours workers have to spend on the job and the years required for workers to retire.

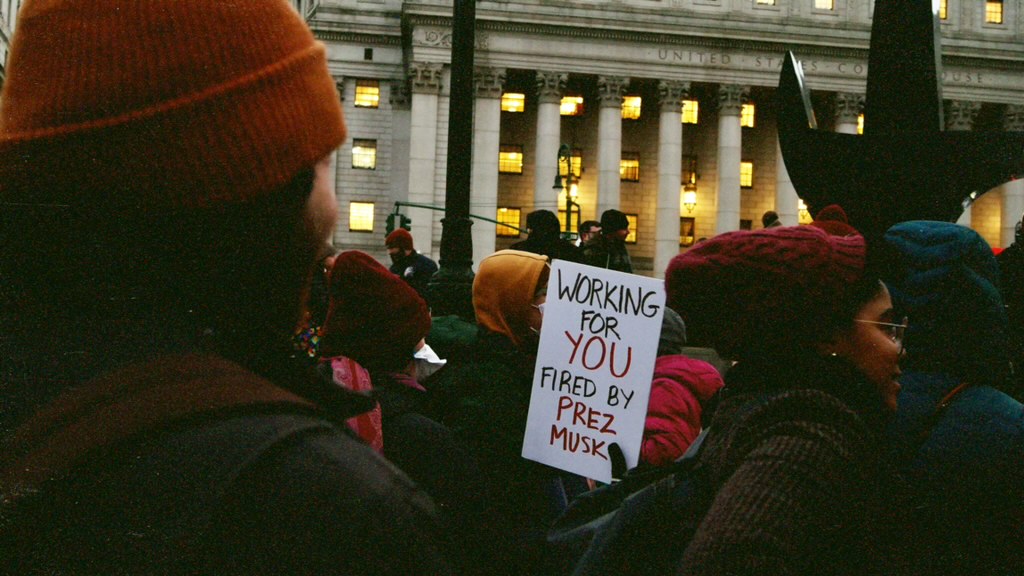

EVs are an important part of the fight against climate change, and the government is now giving automakers massive amounts of money to build new EV plants. We can’t allow tiers to stay and proliferate in this sector; they are a barrier to a just transition. We should file them in the trash right alongside Stellantis’s contract proposal.

A longer form of this article was originally published at Jacobin.